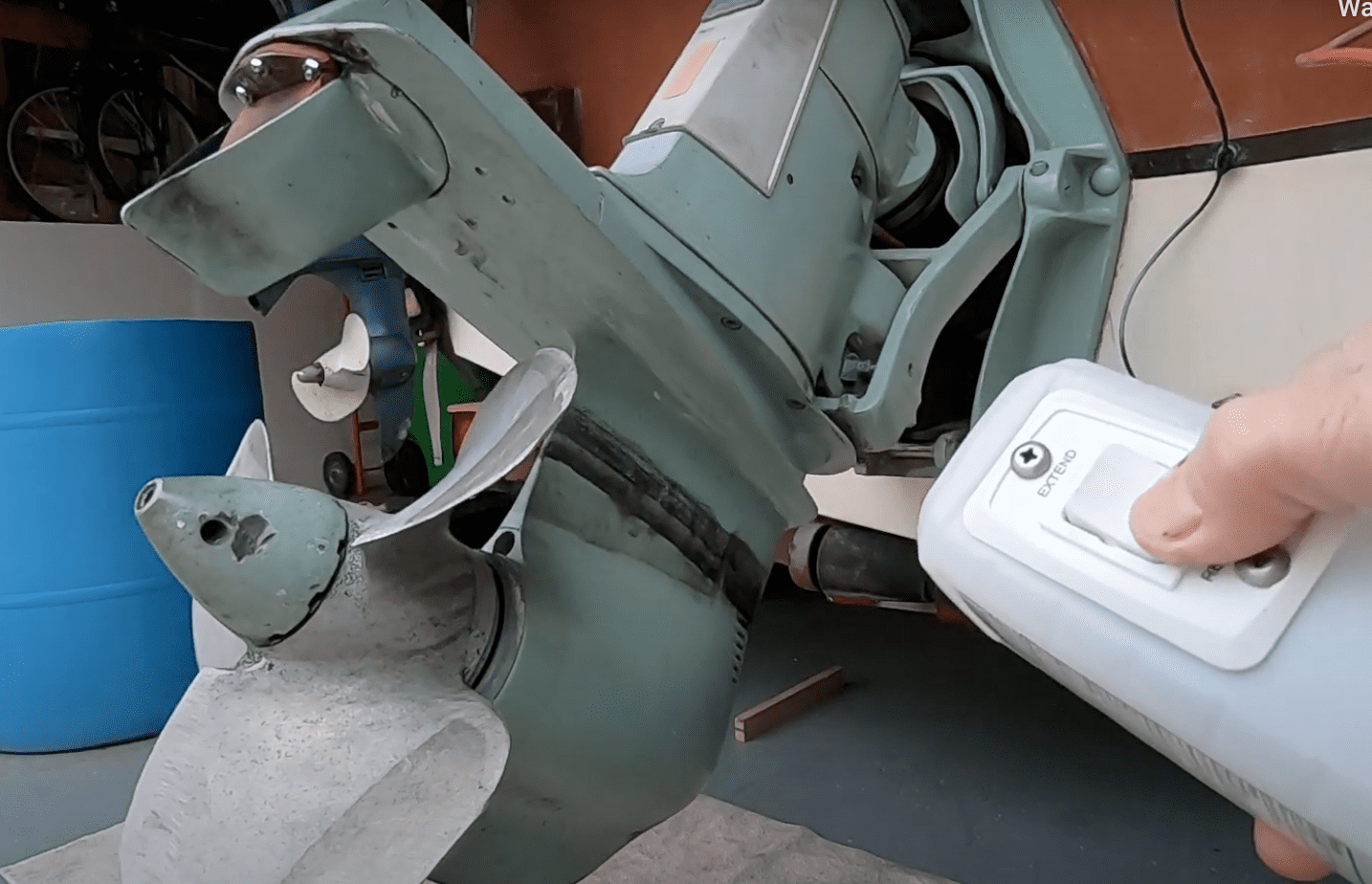

In this tutorial, we are shown a quick method of retrofitting a reverse polarity switch onto a Volvo Penta 270 outdrive. It is quite common for the electrical assembly that provides the method of lift to the outdrive to fail. The relays and switches used in the assembly aren't always up to a marine grade standard. An old vessel may have also had parts chopped and changed over the years.

Whilst this method will work crudely there's a few notes below to consider.

Table of Contents

TIPS AND COMMENTS

Damage To A Motor

Sourcing a motor that is not original or Volvo Penta does pose a few potential issues. It could be to powerful for the task. If a micro switch is not used to stop the motor on the top of the worm drive rotation the outdrive could be damaged. The original worm drive electrical assembly deals with this issue.

A modern motor may be able to deal with the damage that could occur from maxing out. Using a wireless remote where you can have eyes on your outdrive during the lift may mitigate this somewhat.

Electrical Safety

In the above video we didn't see the use of an inline fuse. The installer also uses a non-insulated adjustable spanner to tighten down narrowly avoiding a short.