In this tutorial you will learn the basics of fairing with West System epoxy. This technique can be used to fill voids in surfaces with imperfections, re-shape and build up non-structural areas. It is important that the surface is prepared prior to fairing. The surface should be clean, dried and sanded in preparation for first later of epoxy resin. The first layer of rolled epoxy gives fairing compound a good surface to mechanically bond too. Whilst West System epoxy is used in this video it is possible to use cheaper alternative resins.

The first layer of rolled epoxy gives the fairing compound a good surface to mechanically bond too. This technique can be used on a variety of surfaces but care should be taken when trying to choose a resin that is compatible with the material you are working with.

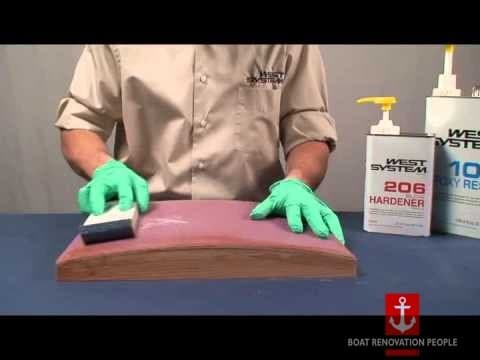

Low spots can be an issue if there isn’t enough fairing compound added to the surfaces. Plastic spreaders: otherwise known as applicators, can be found in automotive stores or ordered online. They work by spreading the fairing compound evenly and eliminating low spots.

Highspots can be removed with a 40 or 50 grit sanding block and finished with an 80 grit orbital sander or a flexible block. Notably, applying several coats of resin after the fairing has been completed will allow for a good seal before the final topcoat.

When I used Epoxy Paints for the workshop, I rent painters, I could not do it myself